Functional surfaces

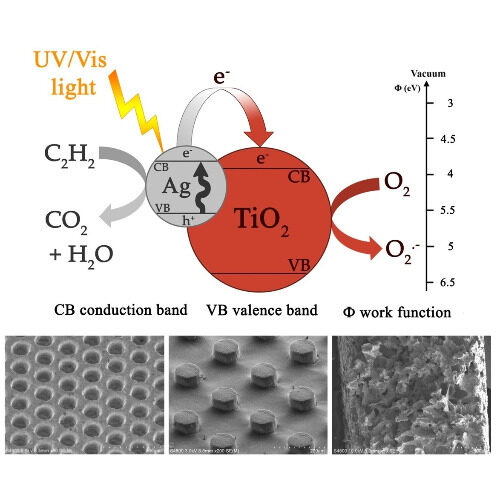

Photocatalysis utilizes light to activate chemical reactions. The most studied photocatalytic material is titanium dioxide (TiO2), which is a widely used white, inert, and non-toxic pigment and semiconductor. The bandgap of TiO2 is 3.2 eV corresponding to the UVA-range that is only approximately 3-5% of the solar spectrum. Therefore, recent research has focused on functionalization of TiO2 structures, for example, with metal nanoparticles that can couple visible light wavelengths for the photocatalytic excitation via plasmonic coupling. This can significantly improve the efficiency of such metal-semiconductor composites. Our research group has concentrated on fabrication and characterization of TiO2 inverse opal structures functionalized with different metallic nanostructures that allow efficient solar-driven chemical reactions.

Metal injection molding (MIM) can be used for cost-effective mass fabrication of three-dimensional metallic structures. Injection molding is a widely used technique that can also be used with metal powders. MIM-technique combined with high-accuracy micro-robotic tools allows fabrication of functional, microstructured metallic surfaces. Additionally, MIM-technique can be used for making porous metals, and various functionalities such anti-corrosion and antibacteriality can be added into the pores. The group’s latest national research initiative, Self‑Guiding Hybrid Materials (funded by the Finnish Transport and Communications Agency/ERDF, running from 1 January 2025 to 31 December 2026), focuses on advancing expertise in ice prevention, maintenance‑free lubrication, surface quality, and low flow friction. The project is carried out within a network formed by research organizations (Aalto University, UEF, Karelia, and TAU) and companies (Abloy, Millidyne, Patrol Traiding, Vaisala, and Valmet Automation).

Microstructured surfaces can have a significant effect on both static and dynamic friction. Our research group has focused on friction between different material pairs (polymers, metals, composites) and how friction can be reduced, for example, by different lubrication agents. One research topic and application area has been high strength joints. The micro- and nanostructured surfaces have a high surface area that has been studied together with coupling chemistry for improved adhesion.

Cooperation

-

Liquid flame spray (LFS) method for nanoparticle deposition, Prof. Jyrki M. Mäkelä

-

Terahertz spectroscopy, Prof. Takeya Unuma

-

Synthesis and characterization of photocatalytic materials, Dr. Salvador Eslava